A Vapour Absorption Refrigeration System (VARS) is a form of refrigeration machine that makes use of a aggregate of a refrigerant and an absorbent to create a cooling effect. In this machine, the refrigerant vapor is absorbed with the aid of using the absorbent, and this combination is then subjected to warmness to launch the refrigerant vapor. The refrigerant is eventually condensed and evaporated to obtain the favored cooling effect. Unlike vapour compression systems, which rely upon mechanical compressors, VARS makes use of a thermal electricity supply to power the refrigeration process. The idea of vapour absorption refrigeration dates again to the early nineteenth century. The preliminary concept become delivered with the aid of using Jacob Perkins in 1834, who created the primary sensible absorption refrigeration machine. Perkins` layout laid the inspiration for destiny trends in absorption refrigeration.

- Basic Principles of Refrigeration

- Components of Vapour Absorption Refrigeration Systems

- Working Principle of Vapour Absorption Refrigeration System

- Types of Absorbent-Refrigerant Combinations

- Advantages and Disadvantages of Vapour Absorption Refrigeration Systems

- Applications of Vapour Absorption Refrigeration Systems

- Design and Operating Parameters

- Performance Evaluation

- FAQ

Basic Principles of Refrigeration

Thermodynamics of Refrigeration

Heat Absorption: The refrigerant absorbs warmness from the gap to be cooled. This warmness absorption happens withinside the evaporator, in which the refrigerant adjustments from a liquid to a vapor, successfully doing away with warmness from the surroundings.

Heat Rejection: The vaporized refrigerant is then compressed (in vapour compression structures) or absorbed (in vapour absorption structures) and transported to the condenser. In the condenser, the refrigerant releases the absorbed warmness to the environment, condensing returned right into a liquid state.

Phase Change: The refrigeration cycle includes segment adjustments of the refrigerant—liquid to vapor withinside the evaporator and vapor to liquid withinside the condenser. These segment adjustments are vital for the warmth absorption and rejection processes.

Types of Refrigeration Systems

Vapour Absorption Refrigeration Systems: Instead of a mechanical compressor, those structures use a warmness supply to force the absorption of the refrigerant vapor through an absorbent. The warmness supply may be sun, waste warmness, or different thermal power reassets.

Thermoelectric Refrigeration Systems: These structures use the Peltier impact to create a temperature distinction among materials, which may be used for cooling. They are normally used for small-scale packages.

Magnetic Refrigeration Systems: These structures function primarily based totally at the magnetocaloric impact, in which the temperature of a magnetic cloth adjustments while uncovered to a magnetic field. This kind continues to be in experimental degrees for maximum packages.

Comparison with Vapour Compression Systems

Energy Source: Vapour compression structures rely upon electric power to force the mechanical compressor, while vapour absorption structures make use of warmness power, which may be derived from waste warmness or renewable reassets.

Efficiency: Vapour compression structures normally have better coefficients of performance (COP) as compared to vapour absorption structures. However, absorption structures may be greater green while waste warmness or sun power is used.

Environmental Impact: Vapour absorption structures may be greater environmentally friendly, specifically while the use of renewable warmness reassets and environmentally benign refrigerants. Vapour compression structures may also use refrigerants which have excessive international warming potential.

Complexity and Cost: Vapour compression structures are normally greater complicated because of the want for mechanical compressors and are normally greater high-priced in phrases of preliminary funding and maintenance. Vapour absorption structures, at the same time as having decrease working charges, may also contain better preliminary charges for device and installation.

Applications: Vapour compression structures are broadly utilized in residential and business cooling packages because of their performance and reliability. Vapour absorption structures are frequently hired in business packages, far flung locations, and in which warmness reassets are effortlessly available.

Components of Vapour Absorption Refrigeration Systems

Absorber

The absorber is a critical element in which the refrigerant vapor is absorbed via way of means of the absorbent answer. The number one characteristic of the absorber is to facilitate the switch of warmth from the refrigerant to the absorbent, taking into consideration powerful cooling. In this procedure, the refrigerant vapor is absorbed into the liquid absorbent, developing a focused answer this is then circulated to the generator.

Function: Absorbs refrigerant vapor from the evaporator, blending it with the absorbent answer.

Design Considerations: Must make sure green touch among refrigerant vapor and absorbent way to maximize warmness absorption.

Generator

The generator is in which the absorbent-refrigerant aggregate from the absorber is subjected to warmness. This warmness reasons the refrigerant to vaporize, setting apart it from the absorbent answer. The vaporized refrigerant is then directed to the condenser, whilst the absorbent answer is back to the absorber to keep the cycle.

Function: Provides the vital warmness to split the refrigerant vapor from the absorbent answer.

Heat Source: Can be powered via way of means of diverse reassets consisting of waste warmness, sun energy, or direct gas combustion.

Condenser

The condenser is liable for liberating the warmth absorbed via way of means of the refrigerant vapor. In this element, the vaporized refrigerant cools and condenses lower back right into a liquid state. The warmness launched at some stage in this section alternate is transferred to the encircling environment, generally thru air or water cooling.

Function: Cools and condenses the refrigerant vapor right into a liquid.

Types: Air-cooled or water-cooled, relying at the utility and to be had resources.

Evaporator

The evaporator is in which the refrigerant absorbs warmness from the distance or substance to be cooled. As the refrigerant liquid evaporates, it absorbs warmness, thereby reducing the temperature of the surroundings. This cooled refrigerant vapor is then directed to the absorber to keep the cycle.

Function: Absorbs warmness from the goal area or medium, inflicting the refrigerant to evaporate.

Design Considerations: Must make sure powerful warmness switch to gain favored cooling performance.

Pump

The pump is used to flow into the absorbent answer among the absorber and the generator. Its function is to hold the glide of the absorbent answer, making sure that it constantly absorbs refrigerant vapor and returns to the generator for warmness-pushed separation.

Function: Circulates the absorbent answer all through the device.

Design Considerations: Must be able to dealing with the precise strain and glide necessities of the device.

Expansion Valve

The growth valve regulates the glide of refrigerant into the evaporator. It reduces the strain of the liquid refrigerant, inflicting it to amplify and funky earlier than getting into the evaporator. This procedure is critical for making sure that the refrigerant can take in warmness effectively withinside the evaporator.

Function: Controls the glide and strain of the refrigerant getting into the evaporator.

Types: Thermostatic growth valves, digital growth valves, or capillary tubes, relying at the device design.

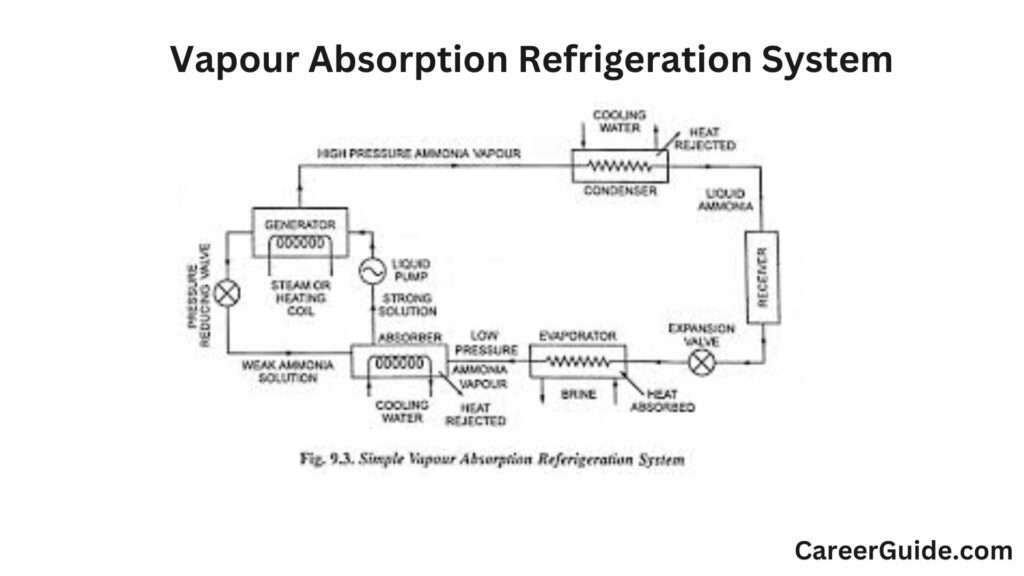

Working Principle of Vapour Absorption Refrigeration System

Cycle Description

The Vapour Absorption Refrigeration System (VARS) operates primarily based totally on a cycle related to the absorption and desorption of refrigerant vapor with the aid of using an absorbent, pushed with the aid of using an outside warmness source. The cycle includes:

Evaporation: In the evaporator, the refrigerant absorbs warmness from the gap or medium being cooled. This reasons the refrigerant to evaporate, transitioning from a liquid to a vapor and reducing the temperature of the encircling area.

Absorption: The vaporized refrigerant then movements to the absorber, in which it’s miles absorbed with the aid of using the absorbent answer. This procedure releases warmness, that is transferred to the encircling environment.

Desorption: The refrigerant-absorbent combination is pumped to the generator, in which outside warmness is applied. This warmness reasons the refrigerant to vaporize and cut loose the absorbent. The vapor then movements to the condenser, whilst the absorbent answer returns to the absorber.

Condensation: In the condenser, the refrigerant vapor releases its absorbed warmness to the environment, condensing lower back right into a liquid.

Expansion: The condensed refrigerant liquid passes thru an enlargement valve, decreasing its stress and temperature earlier than getting into the evaporator to maintain the cycle.

Energy Transfer Mechanisms

Heat Absorption: Occurs withinside the evaporator in which the refrigerant absorbs warmness from the cooled space.

Heat Release: Takes vicinity withinside the condenser, in which the refrigerant releases warmness to the environment.

Desorption Heat Transfer: The generator makes use of outside warmness (e.g., sun or waste warmness) to force the separation of the refrigerant from the absorbent.

Absorption Heat Transfer: The absorbent answer absorbs warmness launched from the refrigerant vapor for the duration of the absorption phase.

Refrigerant and Absorbent Pairing

The performance of VARS relies upon at the refrigerant-absorbent pair:

Water-Lithium Bromide (H₂O-LiBr):

Refrigerant: Water

Absorbent: Lithium Bromide

Applications: Large-scale commercial and industrial cooling.

Ammonia-Water (NH₃-H₂O):

Refrigerant: Ammonia

Absorbent: Water

Applications: Industrial refrigeration, which include in meals processing.

Methanol-Ammonia:

Refrigerant: Methanol

Absorbent: Ammonia

Applications: Specialized situations requiring particular running parameters.

Types of Absorbent-Refrigerant Combinations

Water-Lithium Bromide (H₂O-LiBr)

Refrigerant: Water

Absorbent: Lithium Bromide (LiBr)

Characteristics:

Efficiency: Highly green for huge-scale packages. Water is a great refrigerant because of its excessive latent warmness of vaporization, and lithium bromide is an powerful absorbent.

Applications: Commonly utilized in huge industrial and commercial systems, along with aircon devices for huge homes and commercial processes.

Advantages: Low environmental impact, as water is non-poisonous and lithium bromide answers are enormously safe. High cooling performance.

Limitations: Not appropriate for low-temperature packages (underneath 0°C), and the machine have to be maintained to save you crystallization of LiBr.

Ammonia-Water (NH₃-H₂O)

Refrigerant: Ammonia

Absorbent: Water

Characteristics:

Efficiency: Effective for a extensive variety of temperatures, making it appropriate for numerous commercial packages. Ammonia has a excessive refrigerating capacity.

Applications: Widely utilized in commercial refrigeration systems, which include meals processing, chemical manufacturing, and bloodless garage facilities.

Advantages: High performance and robust refrigerating effect. Ammonia is a great refrigerant with a low international warming potential.

Limitations: Ammonia is poisonous and has a stinky odor, which calls for cautious coping with and protection measures.

Others (e.g., Methanol-Ammonia)

Refrigerant: Methanol

Absorbent: Ammonia

Characteristics:

Efficiency: Methanol is utilized in a few specialised packages in which ammonia won’t be appropriate. The machine can function at a extensive variety of temperatures.

Applications: Used in precise commercial or experimental setups in which conventional pairs aren’t powerful or practical.

Advantages: Flexibility in temperature manipulate and precise use instances in which different pairs might not carry out optimally.

Limitations: Generally much less common, and the machine layout can be extra complicated or much less well-understood in comparison to extra conventional pairs.

Each aggregate has its precise blessings and limitations, making it critical to pick the precise pair primarily based totally on the desired running conditions, performance needs, and protection concerns for the supposed application.

Advantages and Disadvantages of Vapour Absorption Refrigeration Systems

Efficiency and Performance

Advantages:

Utilization of Waste Heat: VARS can efficaciously use low-grade waste warmth or renewable reassets like sun strength, making them appropriate for packages wherein such strength reassets are available.

No Mechanical Compressor: VARS removes the want for a mechanical compressor, decreasing the machine`s transferring elements and probably growing reliability and reducing upkeep requirements.

Long-Term Efficiency: In structures designed for large-scale or non-stop operation, VARS can provide green overall performance, specifically whilst operated along with warmth healing structures.

Disadvantages:

Lower Coefficient of Performance (COP): Generally, VARS have a decrease COP in comparison to vapour compression structures, this means that they’ll be much less green in direct strength use for cooling.

Heat Source Dependency: The overall performance of VARS is exceptionally depending on the provision and temperature of the outside warmth supply. Inadequate warmth can result in decreased efficiency.

Environmental Impact

Advantages:

Reduced Refrigerant Leakage: VARS regularly use refrigerants with decrease international warming ability in comparison to the ones in vapour compression structures, that could decrease environmental harm.

Sustainable Energy Use: By making use of waste warmth or sun strength, VARS can make contributions to sustainable strength practices and decrease reliance on fossil fuels.

Disadvantages:

Potential for Absorbent Corrosion: Some absorbent answers may be corrosive, main to ability environmental risks if now no longer well managed.

Heat Source Impact: If the warmth supply used isn’t renewable or clean (e.g., fossil fuels), the general environmental advantage may be diminished.

Cost Considerations

Advantages:

Lower Operating Costs: In instances wherein waste warmth or sun strength is used, the working prices of VARS may be decrease in comparison to structures that depend totally on electric strength.

Reduced Mechanical Wear: Fewer transferring elements imply probably decrease upkeep and restore prices over the machine`s lifespan.

Disadvantages:

Higher Initial Cost: The preliminary funding for VARS may be better because of the complexity of the machine and the want for specialised additives just like the generator and absorber.

System Complexity: The layout and set up of VARS may be extra complex, which would possibly result in better setup prices and ability demanding situations in reaching greatest overall performance.

In summary, vapour absorption refrigeration structures provide blessings in phrases of the usage of waste warmth and decreasing environmental impact, however they arrive with demanding situations associated with efficiency, cost, and reliance on outside warmth reassets. Evaluating those elements can assist in figuring out the suitability of VARS for unique packages and conditions.

Applications of Vapour Absorption Refrigeration Systems

Industrial Applications

Large-Scale Cooling: Vapour absorption refrigeration structures are regularly utilized in business settings wherein big-scale cooling is required. They are best for strategies that generate big waste warmness, which includes electricity vegetation, chemical manufacturing, and petrochemical industries.

Food Processing and Storage: In the meals industry, VARS are applied for cooling and freezing meals products. The capacity to apply waste warmness from processing vegetation or cogeneration structures complements common efficiency.

Pharmaceuticals and Chemicals: These structures are hired in industries that require unique temperature manage for touchy chemical substances and pharmaceuticals, wherein reliability and occasional environmental effect are crucial.

Commercial Uses

Air Conditioning: VARS are utilized in industrial air con structures, specifically in big homes and buying malls. They can take gain of waste warmness from business strategies or renewable strength reassets, lowering running prices and enhancing efficiency.

Hotels and Resorts: In hospitality settings, which includes motels and resorts, VARS offer cooling for big areas even as probably using sun strength or waste warmness from different on-web website online structures.

District Cooling: In city areas, VARS may be a part of district cooling structures, which give chilled water to more than one homes from a relevant cooling plant, leveraging waste warmness and lowering person constructing cooling prices.

Residential and Transport Applications

Residential Applications: Although much less common, VARS may be utilized in residential packages, specifically wherein sun strength is available. For example, sun-assisted absorption chillers can offer cooling for residential homes in sunny climates.

Transport: VARS are utilized in specialised delivery packages, which includes refrigerated delivery boxes and a few vehicles. They are in particular beneficial wherein extra warmness from engines or different reassets may be harnessed for refrigeration, improving common strength efficiency.

In summary, vapour absorption refrigeration structures are flexible and may be efficaciously applied throughout numerous sectors, from big business packages to industrial and home settings. Their capacity to leverage waste warmness and renewable strength reassets makes them a precious alternative for sustainable and green cooling solutions.

Design and Operating Parameters

Design Considerations

Heat Source: The layout of a vapour absorption refrigeration gadget have to account for the sort and temperature of the to be had warmth supply. Common warmth reassets consist of waste warmth from business processes, sun strength, and direct combustion. The gadget have to be designed to deal with the precise temperature and strain degrees of the warmth supply.

Component Selection: Choosing suitable additives is critical for gadget performance. This consists of deciding on appropriate absorbers, generators, condensers, evaporators, and pumps primarily based totally on the desired cooling ability and running conditions. Each factor have to be matched to make sure most desirable overall performance and longevity.

Refrigerant and Absorbent Pairing: The preference of refrigerant and absorbent impacts the gadget`s overall performance. Common pairs consist of Water-Lithium Bromide (H₂O-LiBr), Ammonia-Water (NH₃-H₂O), and Methanol-Ammonia. The pair ought to be decided on primarily based totally at the preferred temperature range, performance, and environmental considerations.

System Integration: The gadget ought to be incorporated into the present infrastructure, thinking about elements inclusive of area availability, compatibility with different structures, and simplicity of upkeep.

Operating Conditions

Temperature and Pressure: The running conditions, together with the temperature of the warmth supply and the strain inside extraordinary additives, have to be cautiously controlled. The generator calls for excessive temperatures to efficiently separate the refrigerant from the absorbent, even as the absorber and evaporator perform at decrease temperatures and pressures.

Flow Rates: Proper waft fees of the refrigerant and absorbent answers are crucial for keeping gadget performance. This entails adjusting the pump capacities and growth valves to make sure most desirable stream and warmth exchange.

Maintenance and Monitoring: Regular upkeep and tracking of gadget parameters, inclusive of refrigerant levels, absorbent concentration, and factor overall performance, are critical for making sure dependable operation.

Efficiency Optimization

Heat Recovery: Implementing warmth restoration structures can beautify general performance via way of means of reusing waste warmth in the gadget or for different purposes. For example, waste warmth from the generator may be used to preheat the absorbent answer or for auxiliary heating.

Component Efficiency: Ensuring that every factor operates at its designed performance is critical. This entails ordinary upkeep, optimizing factor sizing, and heading off troubles like scaling or fouling in warmth exchangers.

System Tuning: Adjusting gadget parameters, inclusive of the growth valve settings and pump speeds, can optimize overall performance. Fine-tuning those parameters allows in reaching the preferred cooling ability even as minimizing strength consumption.

Insulation and Design Improvements: Proper insulation of additives and pipelines can lessen warmth losses and enhance general gadget performance. Additionally, improvements in factor layout and substances can cause greater green and dependable structures.

Performance Evaluation

Coefficient of Performance (COP)

Definition: The Coefficient of Performance (COP) is a key degree of the performance of a vapour absorption refrigeration device. It is described because the ratio of the cooling effect (or warmness removed) to the enter warmness required for the device to operate.

Significance: A better COP suggests a greater green device. It displays how efficiently the device converts warmness into cooling. While VARS commonly have a decrease COP in comparison to vapour compression structures, they may be frequently selected for his or her capacity to make use of waste warmness and renewable strength sources.

System Efficiency Metrics

Thermal Efficiency: This metric measures how efficiently the device converts enter warmness into beneficial cooling. It entails comparing the warmth enter relative to the refrigeration output. Improvements in thermal performance may be completed via higher warmness healing and optimization of thing overall performance.

Energy Efficiency Ratio (EER): EER is any other metric used to evaluate overall performance, in particular in cooling mode. It is calculated through dividing the cooling capacity (in BTUs in keeping with hour) through the electricity enter (in watts). For VARS, it allows examine cooling overall performance relative to strength intake.

Overall System Efficiency: This consists of comparing the performance of character components (absorber, generator, condenser, etc.) and their integration. Effective device layout guarantees that every thing operates optimally, contributing to the general performance of the device.

Performance Testing and Analysis

Testing Procedures: Performance checking out entails running the device beneathneath diverse situations to evaluate its performance and effectiveness. Key checks consist of measuring the cooling capacity, warmness enter, and COP beneathneath exclusive load and running situations.

Data Collection: Accurate statistics series is critical for overall performance evaluation. Parameters which include temperatures, pressures, go with the drift rates, and strength intake are monitored. This statistics is used to assess device overall performance and pick out regions for improvement.

Performance Analysis: Analyzing take a look at statistics entails evaluating real overall performance towards theoretical or anticipated values. This evaluation allows pick out inefficiencies, which include warmness losses, and affords insights into ability device modifications or optimizations.

Benchmarking: Comparing the overall performance of the VARS with enterprise requirements or comparable structures can offer a benchmark for comparing its performance. Benchmarking allows in know-how how the device plays relative to others in comparable applications.

Frequently Asked Questions (FAQs)

1. What is a Vapour Absorption Refrigeration System?

A Vapour Absorption Refrigeration System (VARS) is a cooling system that uses the process of absorbing refrigerant vapor by an absorbent to generate cooling.

2. How does a Vapour Absorption Refrigeration System work?

The system functions by first allowing the refrigerant to absorb heat and evaporate in the evaporator. This vapor is then absorbed by an absorbent in the absorber, releasing heat. The refrigerant-absorbent mixture is heated in the generator, causing the refrigerant vapor to separate from the absorbent.

3. What are the main components of a Vapour Absorption Refrigeration System?

The key components include the absorber, where the refrigerant vapor is absorbed by the absorbent; the generator, which heats the refrigerant-absorbent mixture to separate the refrigerant vapor; the condenser, which cools and condenses the refrigerant vapor.

4. What are common refrigerant and absorbent pairs used in Vapour Absorption Refrigeration Systems?

Common pairs include Water-Lithium Bromide (H₂O-LiBr), used in large commercial and industrial systems; Ammonia-Water (NH₃-H₂O), suitable for industrial refrigeration; and Methanol-Ammonia, employed in specific applications where other pairs might not be effective.

5. What are the advantages of Vapour Absorption Refrigeration Systems?

VARS have several advantages, including the ability to utilize waste or renewable heat sources, which can reduce operational costs and environmental impact. They also have fewer moving parts compared to vapour compression systems, which can lead to lower maintenance requirements and increased reliability.