A Fluidized Bed Dryer is a form of commercial drying equipment used to dry granular or powdered materials successfully. In this manner, a movement of hot air or gasoline is exceeded through the material, inflicting it to grow to be suspended or “fluidized” inside the air, similar to a boiling liquid. The fluidization creates a dynamic surroundings where the particles are uniformly uncovered to the drying medium, making sure constant and green heat switch. This method is widely used in industries such as pharmaceuticals, food processing, chemicals, and ceramics because of its potential to handle delicate merchandise, uniform drying, and improved heat trade. The Fluidized Bed Dryer is thought for offering quick drying times, power performance, and the protection of the cloth’s great.

- What is a Fluidized Bed Dryer Definition?

- How Does a Fluidized Bed Dryer Work?

- Applications of Fluidized Bed Dryers

- Advantages of Using a Fluidized Bed Dryer

- Key Components of a Fluidized Bed Dryer

- How Fluidized Bed Dryers are Used in Pharmaceutical Manufacturing

- Importance of Temperature and Humidity Control in Fluidized Bed Drying

- Fluidized Bed Dryer in Food Processing:

- FAQ About Fluidized Bed Dryer Definition

What is a Fluidized Bed Dryer Definition?

The Fluidized Bed Dryer Definition refers to a complicated drying technique wherein substances are dried by means of suspending them in a controlled drift of hot air or fuel. This process creates a “fluidized nation” wherein the particles are uniformly mixed and heated, ensuring efficient moisture removal. The Fluidized Bed Dryer Definition is in particular beneficial for drying granular, powdered, or crystalline substances, offering benefits like uniform drying, electricity performance, and upkeep of material properties.

Key Points About Fluidized Bed Dryer

- Uniform Drying: The Fluidized Bed Dryer Definition emphasizes uniform publicity of all debris to the drying medium, main to consistent moisture removal.

- Enhanced Heat Transfer: The fluidized state will increase the surface place for heat trade, improving drying efficiency.

- Shorter Drying Time: Due to green warmth and mass transfer, the Fluidized Bed Dryer Definition ensures faster drying compared to traditional strategies.

- Gentle on Products: It is suitable for warmth-sensitive substances, retaining their physical and chemical residences.

- Customizable Parameters: Temperature, air velocity, and residence time may be adjusted, making the Fluidized Bed Dryer Definition flexible for extraordinary materials.

- Wide Applications: Commonly utilized in prescribed drugs, food processing, chemicals, and fertilizer manufacturing.

How Does a Fluidized Bed Dryer Work?

A Fluidized Bed Dryer Definition describes the manner wherein strong particles are dried with the aid of postponing them in a stream of warm air or gasoline, creating a fluid-like conduct. This country lets in for uniform warmness and mass switch, which ensures green moisture elimination from the fabric. The drying system is widely used in industries along with prescribed drugs, meals processing, and chemicals.

Key Points on How a Fluidized Bed Dryer Works

- Introduction of Air or Gas: Hot air or fuel is introduced through a perforated distributor plate, developing an upward glide that suspends the debris.

- Fluidization of Particles: The Fluidized Bed Dryer Definition emphasizes the nation wherein debris are lifted and blended, mimicking the behavior of a fluid.

- Efficient Heat Transfer: The fluidized debris come into direct touch with the drying medium, making sure speedy and uniform heat switch.

- Moisture Removal: As warm air passes thru the fluidized cloth, moisture evaporates, and the humid air is vented out of the device.

- Temperature Control: Precise manage over the drying temperature is maintained to keep away from overheating and degradation of heat-touchy materials.

- Residence Time: The drying time can be adjusted by using controlling the air speed and cloth go with the flow fee.

- Product Collection: After achieving the desired moisture content material, the dried debris are amassed at the release point.

- Dust Control: Cyclones or bag filters are often integrated to capture fine particles and make certain clean exhaust air, aligning with the Fluidized Bed Dryer Definition.

Applications of Fluidized Bed Dryers

- Pharmaceutical Industry: Used for drying granules and powders in tablet production and particular formulations.

- Food Processing: Ideal for drying spices, grains, coffee, and powdered meals merchandise.

- Chemical Industry: Efficiently dries catalysts, polymers, and unique powdered chemical substances.

- Fertilizer Production: Used to dry granular fertilizers like urea and ammonium nitrate.

- Minerals and Metals: Applied in drying powdered ores, pigments, and minerals.

- Ceramics and Glass: Suitable for drying ceramic powders and great glass substances.

- Waste Management: Aids in drying sludge and bio-waste for much much less complex coping with and disposal.

- Cosmetic Industry: Used for drying powdered factors in beauty and private care merchandise.

- Powder Coatings: Dries powdered coatings used within the car and system industries.

Advantages of Using a Fluidized Bed Dryer

- Uniform Drying: The Fluidized Bed Dryer Definition ensures that all particles are uniformly exposed to the drying medium, preventing choppy moisture content material.

- Rapid Drying Process: Due to efficient warmness and mass switch, substances dry faster as compared to standard drying strategies.

- Energy Efficiency: The procedure minimizes strength intake through optimizing warmness switch and decreasing drying time.

- Gentle on Heat-Sensitive Materials: With unique temperature control, the Fluidized Bed Dryer Definition is good for drying materials which might be touchy to high warmth.

- Improved Product Quality: The fluidized kingdom prevents clumping or overheating, retaining the fabric’s bodily and chemical residences.

- Customizable Design: Parameters including air velocity, temperature, and residence time can be tailored to specific materials and approaches.

- Dust Control: Integrated dust series systems reduce particulate emissions, ensuring purifier operations.

- Scalability: The technology is to be had in various sizes, making it appropriate for small-scale studies to huge commercial manufacturing.

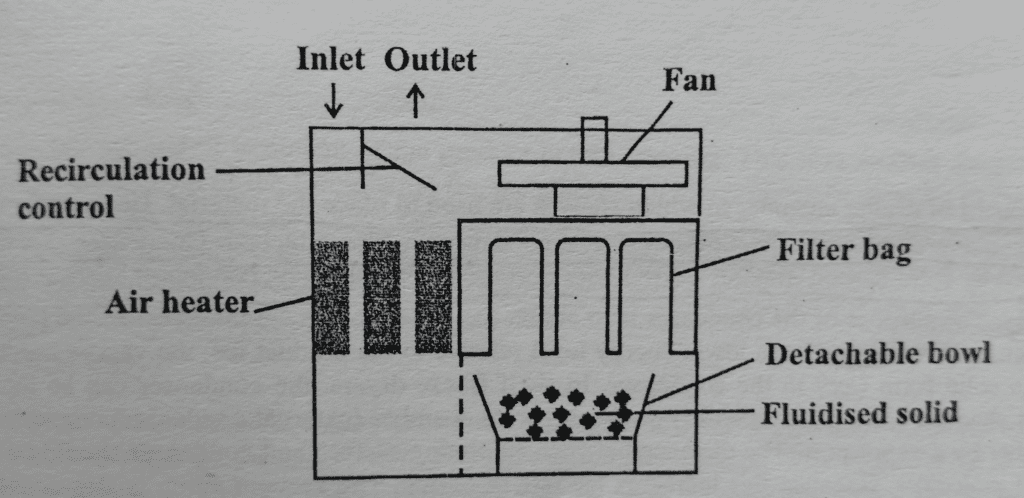

Key Components of a Fluidized Bed Dryer

- Air Distributor Plate: This perforated plate ensures uniform airflow, a fundamental issue of the Fluidized Bed Dryer Definition, for green fluidization of particles.

- Blower or Fan: Provides the desired airflow to droop and blend particles, creating the fluidized state.

- Heating System: Generates warm air or fuel that serves because the drying medium, important for achieving effective drying.

- Drying Chamber: The crucial compartment in which debris are fluidized and moisture is removed. Its design helps uniform warmness and mass switch.

- Exhaust System: Removes humid air and forestalls the accumulation of excess moisture in the device, making sure adherence to the Fluidized Bed Dryer Definition.

- Temperature and Pressure Controls: These controls keep top-quality running situations, protecting warmness-touchy substances and making sure power efficiency.

- Dust Collection System: Cyclones or bag filters seize nice debris, keeping clean exhaust air and reducing material loss.

- Material Feed and Discharge System: Facilitates the continuous or batch loading and unloading of materials at the same time as minimizing downtime.

How Fluidized Bed Dryers are Used in Pharmaceutical Manufacturing

- Drying of Granules: Fluidized mattress dryers are extensively used to dry wet granules organized all through the granulation process in tablet manufacturing.

- Moisture Removal from Powders: The era ensures even and rapid drying of powders, a critical step for stable and constant formulations.

- Preparation of Excipients: The Fluidized Bed Dryer Definition highlights its potential to dry excipients like lactose and microcrystalline cellulose efficiently.

- Heat-Sensitive Material Handling: With particular temperature control, it dries materials sensitive to warmth with out compromising their chemical integrity.

- Coating Processes: Fluidized bed dryers are adapted for coating debris with polymers or different materials, allowing managed drug release.

- Drying of Active Pharmaceutical Ingredients (APIs): The manner is ideal for APIs, preserving their stability and efficacy.

- Reduction of Drying Time: Compared to traditional strategies, fluidized bed dryers extensively cut down drying time, increasing productivity.

- Uniform Drying: Ensures that all particles acquire a constant moisture content, vital for uniform tablet compression and overall performance.

Importance of Temperature and Humidity Control in Fluidized Bed Drying

- Maintaining Product Quality: Controlling temperature prevents warmth-touchy substances from degrading, making sure the integrity of pharmaceutical and meals merchandise.

- Efficient Moisture Removal: Proper humidity regulation lets in for uniform and thorough drying, a key principle of the Fluidized Bed Dryer Definition.

- Energy Efficiency: Precise control minimizes electricity waste through preventing overheating or excessive drying times.

- Avoiding Overdrying: Overdrying can harm cloth homes or result in excessive fines; humidity control mitigates this risk.

- Preventing Material Degradation: Sensitive substances like active pharmaceutical substances (APIs) require tight temperature law to keep away from chemical modifications.

- Enhancing Process Consistency: Stable temperature and humidity create reproducible outcomes, a center advantage emphasized in the Fluidized Bed Dryer Definition.

- Reducing Equipment Wear: Controlled situations save you overheating, lowering strain on the system and increasing its lifespan.

- Improved Safety: Monitoring temperature and humidity reduces dangers of dirt explosions or overheating, ensuring more secure operations.

Fluidized Bed Dryer in Food Processing:

- Preservation of Nutritional Value: Fluidized bed dryers help maintain the dietary content material of food via the use of controlled temperatures, reducing the hazard of nutrient loss in the course of drying.

- Improved Drying Efficiency: This drying approach lets in for uniform moisture removal, a key benefit highlighted inside the Fluidized Bed Dryer Definition, resulting in everyday food products.

- Gentle Drying of Delicate Foods: Food gadgets which might be sensitive to warmth, like herbs and spices, benefit from the mild drying approach of fluidized bed dryers, which keeps their shade, taste, and aroma.

- Processing of Bulk Food Products: For huge-scale meals manufacturing, fluidized mattress dryers make sure green drying of bulk substances like grains, seeds, and legumes.

- Faster Drying Times: Compared to conventional techniques, fluidized mattress dryers extensively reduce drying time, enhancing productiveness in meals processing.

- Preventing Clumping and Sticking: The fluidized mattress drying approach ensures that particles continue to be suspended and dry frivolously, preventing clumping or sticking, that could arise with different strategies.

- Energy Efficiency: By optimizing airflow and temperature manage, fluidized mattress dryers are power-inexperienced, it really is essential in big-scale meals processing operations.

- Improved Shelf Life: Removing excess moisture from food merchandise prevents spoilage, enhancing the shelf life and stability of the final products.

FAQ About Fluidized Bed Dryer Definition

1.What is a Fluidized Bed Dryer?

A Fluidized Bed Dryer is a drying equipment that uses a stream of hot air to suspend and fluidize the material to be dried. This allows for efficient heat transfer and rapid drying of particulate materials.

2 How Does a Fluidized Bed Dryer Work?

The process involves passing air through a bed of granular or powdered material at a velocity that is sufficient to suspend the particles. The particles behave like a fluid, allowing uniform drying and heat distribution.

3.What Are the Main Advantages of a Fluidized Bed Dryer?

Some key benefits include high drying efficiency, uniform heat distribution, short drying times, and the ability to handle both small and large particles. It also provides better control over temperature and humidity.

4 What Materials Are Suitable for Fluidized Bed Drying?

Fluidized bed dryers are ideal for drying granular or powdered materials such as food products, pharmaceuticals, chemicals, and minerals, where uniform drying is important.