Screw Gauge: Definition, Working Principle

- Mechanical Engineering

-

Aug 08

- Share post

A screw gauge is a device used to measure the linear dimensions of small objects with great accuracy. It is a precision instrument that consists of a calibrated screw, a thimble, and a pinion. The screw is rotated by the pinion, and the movement of the screw is transmitted to the thimble, which is graduated in micrometers. This allows the user to read the linear dimension of the object with great accuracy.

- Introduction to Screw Gauge: A Prelude to Precision

- Decoding the Screw Gauge Formula: A Mathematical Symphony of Measurements

- Diagram of a Screw Gauge: Navigating the Intricate Anatomy

- Precision Measurements with Screw Gauge: Unveiling the Micrometer Method

- The Inch Micrometer Unveiled: A Journey into Imperial Measurements

- Working Principle of Screw Gauge: Threads, Rotations, and Precision Unleashed

- Versatility in Precision: The Multifaceted Applications of Screw Gauge

- Mastering the Art: Key Guidelines for Effective Screw Gauge Usage

- Navigating the Past: Exploring Previous Year Questions

- Putting Knowledge to the Test: Sample Questions for Self-Assessment

- Conclusion

- FAQ

1. Introduction to Screw Gauge: A Prelude to Precision

In the realm of precision measurement, a remarkable instrument takes center stage – the screw gauge. As a marvel of engineering, it allows us to delve into the minutiae of dimensions, enabling accurate readings in realms where accuracy is paramount. In this chapter, we embark on a journey to understand the significance of the screw gauge in modern measurement practices.

2. Decoding the Screw Gauge Formula: A Mathematical Symphony of Measurements

In the realm of instrumentation, each device is underpinned by a fascinating scientific foundation, and the screw gauge stands as a quintessential example. In the following chapters, we embark on an illuminating journey that delves deep into the realm of precision measurement. Our exploration transcends the physicality of the screw gauge to unveil the captivating interplay between scientific principles and practical utility.

As we embark on this voyage, we’ll unravel the intricate web of mathematical elegance that intricately governs the realm of screw gauge measurements. The process involves an awe-inspiring decryption of the formula that ingeniously converts rotational motion into meticulously calibrated linear measurements. The symphony of calculations and mechanics merges seamlessly, transforming mere turns of the screw into accurate depictions of physical dimensions.

Prepare to be enthralled by the seamless fusion of mathematics and engineering, where theory and application harmoniously dance to orchestrate precision. Throughout this journey, you’re invited to witness the harmonious synchronization of two seemingly disparate domains, culminating in the creation of an instrument that redefines our understanding of accurate measurement.

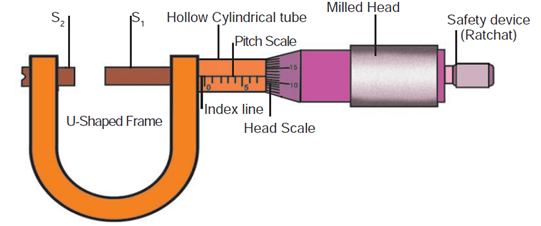

3. Diagram of a Screw Gauge: Navigating the Intricate Anatomy

The process of comprehending intricate instruments often finds a valuable ally in visualization, illuminating the labyrinthine pathways of their inner mechanisms. In the upcoming chapters, we embark on an illuminating voyage that transcends the confines of theory, allowing us to traverse the tangible landscape of a screw gauge’s architecture. Our expedition offers a captivating visual odyssey, guiding us through a meticulously curated tour of the various components that constitute this remarkable instrument.

As we delve into this visual exploration, we unmask the intricate anatomy of the screw gauge, peering into its fundamental building blocks with keen curiosity. With each unveiling of a component, we glean insights into its unique function and contribution to the symphony of measurement. This journey delves beyond the superficiality of individual parts, connecting the dots between gears, threads, and mechanisms, painting a comprehensive picture of their collective interplay.

Our immersive foray into the heart of the screw gauge’s composition not only deepens our understanding but also paves the way for a more profound comprehension of its operational intricacies. By unveiling the roles each part undertakes in the measurement process, we set the stage for a broader and more holistic grasp of the instrument’s functionality. This immersive voyage serves as a gateway to a profound appreciation of the science behind the gauge, empowering us to unravel the mysteries it holds and harness its precision to its fullest potential.

4. Precision Measurements with Screw Gauge: Unveiling the Micrometer Method

Embarking upon an immersive exploration into the realm of precision, we embark on a journey of discovery that delves deep into the heart of screw gauge functionality. Here, we unfurl the intricacies of the revered micrometer method, a finely tuned technique harnessed by screw gauges to unravel the most minuscule measurements. Prepare to traverse step by step through a meticulous unraveling, as we decode the art and science behind making accurate measurements that transcend the boundaries of the visible.

With unwavering attention to detail, we peel back the layers that shroud the micrometer method, exposing the inner workings that facilitate its remarkable precision. Each turn of the screw becomes a crucial note in the symphony of measurement, orchestrating a harmonious dance between mechanics and mathematics. As we meticulously guide you through this process, you’ll bear witness to the fascinating synergy between human ingenuity and scientific principles, culminating in a masterpiece of precision measurement.

The micrometer attachment, a testament to ingenious design, emerges as a guiding beacon in our pursuit of accuracy. Through its calibrated mechanisms, we navigate the intricate terrain of measurement, fine-tuning our readings to levels that transcend the limits of perception. This transformation is akin to peering through a magnifying glass, revealing hidden worlds of quantification that remain imperceptible to the naked eye.

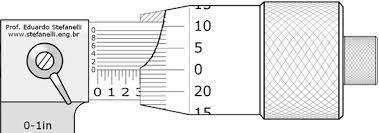

5. The Inch Micrometer Unveiled: A Journey into Imperial Measurements

In the vast landscape of measurement systems, while the metric system stands as the reigning champion, the echoes of imperial measurements persist in specific realms, stubbornly maintaining their foothold. In the following chapter, we embark on an illuminating expedition that unravels the role of inch micrometers within the intricate tapestry of screw gauge measurements. This journey of exploration peels back the layers, revealing a world where imperial units aren’t mere relics but essential tools that shape the foundation of precision.

As we navigate through the complex interplay of measurement systems, inch micrometers emerge as stalwart companions, facilitating the translation of minute distances into comprehensible dimensions. Within the context of screw gauge measurements, these inch-based instruments play a pivotal role, enabling us to interact with the tangible manifestations of precision. Their calibration and mechanisms become conduits that bridge the gap between theoretical concepts and tangible reality, enabling engineers and scientists alike to transcend the abstract and engage directly with the measurable.

In industries where imperial units reign supreme, inch micrometers are the linchpin that harmonizes the demands of accuracy with the familiarity of established standards. This chapter illuminates their invaluable contribution, unveiling how these instruments seamlessly intertwine with screw gauge measurements to produce results that resonate with historical foundations and modern demands. It’s a narrative that underscores the continuity of knowledge across epochs, as we harness the principles of the past to shape the advancements of the present and future.

6. The Inch Micrometer Unveiled: A Journey into Imperial Measurements

Nestled within the core of every instrument beats a foundational principle, a driving force that breathes life into its functionality. In this chapter, we embark on an exhilarating voyage of exploration, delving into the very essence of screw gauges and peeling back the layers that shroud their working principle. Our journey takes us deep into the intricate mechanisms that orchestrate the symphony of measurements, unraveling a captivating interplay between threads, rotations, and the art of calibrated precision.

As we navigate the labyrinthine pathways of screw gauge mechanics, we uncover a mesmerizing dance of components that harmonize to yield precise results. Threads, those seemingly unassuming helical contours, transform into conduits of accuracy, translating rotational motion into tangible dimensions with remarkable finesse. The symmetrical turns of the screw, once a mundane gesture, emerge as the catalysts that usher forth a world of calibrated exactitude.

With every incremental movement, the screw gauge unveils a realm where precision is not just an aspiration but an attainable reality. The rotations are no mere revolutions; they’re the key to unlocking a treasury of accurate measurements. Each twist of the screw unfurls a new chapter in the saga of measurement, offering a glimpse into a world where infinitesimal variations bear the potential to alter the course of innovation.

In this symphony of mechanics, calibrated precision emerges as the guiding star. Every intricately crafted thread, every calculated rotation, converges to create an instrument that transforms measurements into a realm of unparalleled exactness. The carefully honed mechanisms weave a narrative of meticulous craftsmanship, culminating in a device that stands as a testament to human ingenuity and the pursuit of mastery over dimensions.

7. Versatility in Precision: The Multifaceted Applications of Screw Gauge

The applications of screw gauges are as diverse as the fields they serve. From measuring threads to calibrating instruments, their utility transcends disciplines. In this chapter, we explore the multifaceted roles screw gauges play in various industries, underscoring their significance as indispensable tools of precision.

8. Mastering the Art: Key Guidelines for Effective Screw Gauge Usage

While instruments provide the means, expertise elevates the process. We delve into the art of effectively using a screw gauge, unraveling key guidelines and precautions that ensure accurate measurements. This chapter equips you with the knowledge to wield this precision instrument with finesse.

9. Navigating the Past: Exploring Previous Year Questions

Preparation often involves revisiting the past. Here, we delve into a selection of previous year questions that test your understanding of screw gauges. By navigating these questions, you’ll not only consolidate your knowledge but also gain insights into the diverse ways screw gauge concepts are tested.

10. Putting Knowledge to the Test: Sample Questions for Self-Assessment

As we near the conclusion of our exploration, it’s time to put your acquired knowledge to the test. Engage in a series of sample questions designed to challenge your comprehension of screw gauges. This self-assessment serves as a capstone to your journey through the intricacies of this remarkable instrument.

11. Conclusion

Embarking on this all-encompassing odyssey, we have meticulously unraveled the intricate layers that enshroud the enigmatic screw gauge, unfurling a tapestry that unveils its inner mechanisms, far-reaching applications, and profound significance within the realm of precision measurement. As we stand at the precipice of knowledge, peering through the window of exploration, we are greeted with a panoramic view that spans the depths of its purpose and potential.

Contemplating the myriad dimensions of screw gauge functionality, we find ourselves immersed in a contemplative journey that transcends the mere mechanics of its operation. With each revelation, we traverse through the landscape of its applications, witnessing its transformative impact across diverse sectors. From the precision-driven world of engineering to the scientific realms that demand unerring accuracy, the screw gauge emerges as an irreplaceable instrument, a sentinel of precision in a world of complexity.

In this reflective juncture, as your thoughts intertwine with the intricate workings of the screw gauge, you will find yourself equipped with not merely knowledge, but a profound understanding that reaches into the very essence of this marvel of engineering. The artistry of its design, the symphony of its mechanics, and the finesse of its application all coalesce to illuminate the multifaceted brilliance that defines the screw gauge.

Whether you stand as an aspiring engineer, seeking to unravel the secrets of precision, a curious student eager to fathom the depths of measurement, or an ardent lover of precision who revels in the elegance of accurate quantification, this expedition serves as a beacon of enlightenment. It enriches your appreciation for the meticulous art and rigorous science that underlie the realm of measurement, inviting you to delve deeper into the intricate world of instruments that shape our understanding of the universe. As you emerge from this transformative journey, you carry with you a legacy of insight, ready to embrace new challenges armed with a profound appreciation for the timeless interplay between artistry and science.

12. FAQ

A screw gauge, also known as a micrometer screw gauge, is a precision measuring instrument used to determine small distances or thicknesses with a high degree of accuracy. It employs a screw mechanism to translate rotational motion into linear displacement, enabling precise measurements.

The working principle of a screw gauge involves the interaction between threads and rotations. As the screw is turned, the spindle moves along the threads, causing linear displacement. By measuring the number of rotations and fractional rotations, the screw gauge can accurately determine distances.

The formula for screw gauge measurement is given by:

Measurement = (Number of Main Scale Divisions) × (Value of One Main Scale Division) + (Number of Circular Scale Divisions) × (Value of One Circular Scale Division)

Screw gauges find extensive applications in various fields, including:

Measuring the diameter of wires and cylinders

Determining the thickness of sheets, films, and materials

Calibrating precision instruments

Checking the pitch and lead of threads

Quality control in manufacturing processes

Screw gauges offer high accuracy, often capable of measuring distances up to micrometers (µm) or even nanometers (nm) depending on the instrument’s precision. The accurate interplay between threads and rotations ensures reliable measurements.

Yes, there are different types of screw gauges, including the standard micrometer screw gauge and the inch micrometer. Standard micrometers measure distances in metric units, while inch micrometers are used in industries where imperial units are prevalent.

MBA Exams

Top Searches

Jee Mains

Jee Advance

STUDENTS

- For 9th class

- Skill Based Career Test |

- Services |

- Basic Plan |

- Advance Plan |

- Video Counselling Plan |

- Mentorship Plan

- For 10th class

- Stream Selector Test |

- Ideal Career Test |

- Services |

- Basic Plan |

- Advance Plan |

- Video Counselling Plan |

- Mentorship Plan

- For 11th class

- Ideal Career Test |

- Engineering Branch Selector |

- Humanities Career Selector |

- Commerce Career Selector |

- Services |

- Basic Plan |

- Advance Plan |

- Video Counselling Plan|

- Mentorship Plan

- For 12th class

- Ideal Career Test |

- Engineering Branch Selector |

- Humanities Career Selector |

- Commerce Career Selector |

- Services |

- Basic Plan |

- Advance Plan |

- Video Counselling Plan |

- Mentorship Plan

- For B.Com

- Commerce Career Selector |

- Ideal Career Test |

- Services |

- Basic Plan |

- Advance Plan |

- Video Counselling Plan |

- Mentorship Plan

- For B.Sc

- Ideal Career Test |

- Professional Skill Index Test |

- Services |

- Basic Plan |

- Advance Plan |

- Video Counselling Plan |

- Mentorship Plan

- For B.Tech

- Ideal Career Test |

- Professional Skill Index Test |

- Services |

- Basic Plan |

- Advance Plan |

- Video Counselling Plan |

- Mentorship Plan

- For B.A

- Ideal Career Test |

- Humanities Career Selector |

- Professional Skill Index Test |

- Services |

- Basic Plan |

- Advance Plan |

- Video Counselling Plan |

- Mentorship Plan

- For MBA

- Ideal Career Test |

- Professional Skill Index Test |

- Services |

- Basic Plan |

- Advance Plan |

- Video Counselling Plan |

- Mentorship Plan

- For Masters

- Professional Skill Index Test |

- Services |

- Basic Plan |

- Advance Plan |

- Video Counselling Plan |

- Mentorship Plan

STUDY ABROAD

Copyright © CareerGuide.com

Build Version:- 1.0.0.0

- X

- Telegram

- Tumblr

- VKontakte

- Copy link

- Share via...