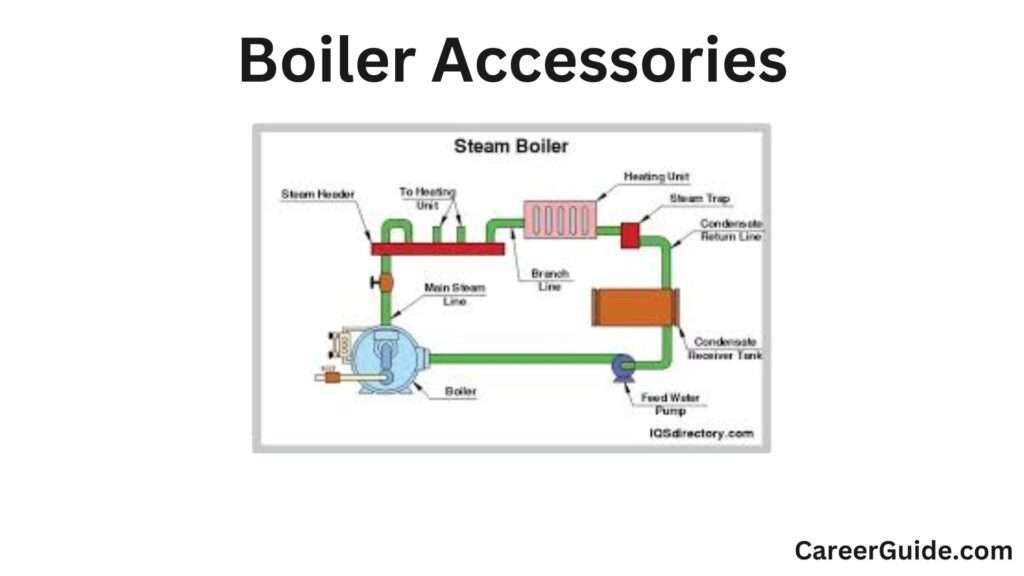

Boiler Accessories are important additives designed to decorate the performance, protection, and ordinary overall performance of boiler systems. They consist of gadgets like strain gauges, protection valves, and water stage indicators, every serving a selected feature to make certain the boiler operates easily and safely. The number one cause of those add-ons is to reveal and manipulate diverse components of boiler operation, which includes strain, water levels, and temperature. By keeping foremost situations and stopping ability hazards, those add-ons play a important position in enhancing boiler performance and longevity, in the long run contributing to a more secure and extra dependable boiler system.

Pressure Gauges in Boiler Accessories

Function and Importance

Safety: Ensuring that the boiler operates inside its designed strain limits, stopping overpressure conditions that could result in system harm or protection hazards.

Efficiency: Allowing operators to modify and optimize boiler overall performance primarily based totally on strain readings.

Preventive Maintenance: Identifying ability problems early with the aid of using detecting unusual strain fluctuations.

Types of Pressure Gauges

Several sorts of strain gauges are utilized in boiler systems, every with precise functions perfect for unique programs:

Bourdon Tube Pressure Gauges:

Description: These gauges use a curved tube that straightens as strain increases, transferring a pointer on a dial.

Application: Commonly used for fashionable strain size in numerous industries.

Diaphragm Pressure Gauges:

Description: These gauges use a bendy diaphragm that deflects with strain changes, translating right into a strain reading.

Application: Suitable for measuring low to mild pressures and for programs in which corrosion or infection is a concern.

Capsule Pressure Gauges:

Description: These gauges use a couple of steel drugs that amplify and settlement with strain changes.

Application: Ideal for low-strain measurements and in which excessive accuracy is needed.

Digital Pressure Gauges:

Description: These gauges use digital sensors to degree strain and show the consequences digitally.

Application: Used for excessive-precision programs and in which virtual readouts are favored for simpler interpretation.

Installation and Maintenance

Proper set up and upkeep are important for making sure correct readings and prolonging the existence of strain gauges:

Installation:

Location: Install the gauge in a area this is effortlessly on hand and farfar from immoderate vibration or heat.

Mounting: Ensure the gauge is installed securely and aligned effectively to keep away from harm.

Connection: Use suitable fittings and make sure there aren’t anyt any leaks at the relationship points.

Maintenance:

Calibration: Regularly calibrate the gauge to make sure accuracy. Calibration need to be carried out in step with the manufacturer`s recommendations.

Inspection: Periodically take a look at for symptoms and symptoms of wear, corrosion, or harm. Replace any elements which might be defective or worn out.

Cleaning: Keep the gauge easy and freed from particles to save you obstruction or fake readings.

Common Issues and Troubleshooting

Pressure gauges can come across numerous problems that have an effect on their overall performance. Here are a few not unusualplace issues and their solutions:

Inaccurate Readings:

Causes: Misalignment, mechanical harm, or calibration problems.

Solution: Recalibrate the gauge, take a look at for alignment problems, and investigate for any mechanical harm.

Fluctuating Readings:

Causes: Pressure surges or vibrations.

Solution: Install dampers or snubbers to lessen strain fluctuations and vibrations.

Leaking Connections:

Causes: Poor set up or tired seals.

Solution: Tighten connections and update seals as needed.

Broken Gauge:

Causes: Physical harm or inner malfunction.

Solution: Replace the gauge if it’s far broken past restore or if it maintains to

malfunction after troubleshooting.

Safety Valves in Boiler Accessories

Safety valves are critical additives in boiler structures designed to save you overpressure and make sure secure operation. They mechanically launch extra strain to save you harm or catastrophic failure, safeguarding each the system and operators. By retaining strain inside secure limits, protection valves assist keep away from risky situations that might cause explosions or mechanical breakdowns.

Role in Boiler Safety

The number one characteristic of protection valves is to guard the boiler from overpressure via way of means of freeing steam or fluid whilst strain exceeds a predetermined level. This characteristic is critical for stopping risky strain build-ups, that may in any other case cause extreme injuries or harm. Safety valves are vital for retaining secure running situations and making sure compliance with protection requirements and regulations.

Types of Safety Valves

Several sorts of protection valves are utilized in boiler structures:

Spring-Loaded Safety Valves: These are the maximum not unusualplace and use a spring to preserve the valve closed. When strain surpasses the set limit, the spring compresses, inflicting the valve to open and launch strain.

Pilot-Operated Safety Valves: These use a pilot valve to govern a bigger principal valve. The pilot valve opens at a decrease strain, which triggers the primary valve to launch extra strain. They are best for high-strain structures requiring unique manipulate.

Direct-Operating Safety Valves: These valves open at once in reaction to strain adjustments with out extra mechanisms, appropriate for packages desiring short reaction.

Balanced-Bellows Safety Valves: Utilizing a bellows mechanism, those valves offer extra correct manipulate and are beneficial in packages with massive strain fluctuations.

Selection Criteria

Choosing the proper protection valve entails numerous considerations:

Pressure Rating: The valve need to cope with the most strain of the boiler, with a score better than the most running strain.

Size and Capacity: The valve must be sized to address the waft price of steam or fluid.

Material Compatibility: Ensure the valve fabric is well suited with the fluids it’s going to cope with, thinking about elements like corrosion resistance.

Operating Conditions: Evaluate the environment, along with temperature and corrosive substances, to pick a valve acceptable to those situations.

Compliance with Standards: Verify that the valve meets applicable protection requirements and regulations, including the ones from ASME or API.

Testing and Calibration

Regular trying out and calibration of protection valves are vital:

Testing: Periodic checks affirm the valve opens at the proper set strain. Testing must be carried out the usage of a take a look at bench or on-site, primarily based totally on producer hints and enterprise requirements.

Calibration: Adjust the valve to make sure it opens at the proper strain setting. Calibration must be a part of everyday maintenance.

Inspection: Inspect for wear, harm, or corrosion and update defective elements as needed.

Water Level Indicators in Boiler Accessories

Water stage signs are vital for keeping the secure and green operation of boiler systems. They screen the water stage in the boiler, stopping troubles like overheating and ability harm because of insufficient water tiers.

Purpose and Function

The number one characteristic of water stage signs is to offer real-time facts at the water stage in a boiler. This is important for:

Safety: Ensuring the water stage stays inside secure working limits to save you dry firing, that can result in overheating and harm.

Efficiency: Maintaining most desirable water tiers improves warmth switch performance and enables keep away from scaling and corrosion.

Operational Control: Allowing operators to modify water tiers as had to keep boiler overall performance and save you operational troubles.

Types of Water Level Indicators

Different styles of water stage signs are utilized in boiler systems, every proper to particular applications:

Float Type Indicators:

Description: Utilizes a go with the flow that actions with the water stage, linked to a mechanical or digital sensor to show the stage.

Application: Commonly used for his or her simplicity and reliability.

Transparent Glass Tubes:

Description: Features a vertical glass tube wherein the water stage is visible.

Application: Typically utilized in smaller or older boilers for visible monitoring.

Electro-Mechanical Indicators:

Description: Employs electric sensors located at diverse tiers to offer readings.

Application: Ideal for present day boilers requiring particular and automatic monitoring.

Conductivity Type Indicators:

Description: Measures the conductivity of water the usage of probes at distinctive tiers to decide the water stage.

Application: Suitable for various water qualities, as they may be much less laid low with impurities.

Installation Procedures

Proper set up is essential for correct and dependable operation:

Location: Install the indicator wherein it’s miles without problems reachable and visible. Avoid regions with excessive temperatures or immoderate vibrations.

Alignment: Ensure accurate alignment with the boiler`s water stage for correct readings. For glass tube signs, particular alignment is vital.

Connection: Securely join the indicator to the boiler, making sure all electric connections are well insulated.

Calibration: Follow manufacturer`s commands for calibration to keep correct readings.

Maintenance and Common Issues

Regular preservation guarantees dependable overall performance:

Inspection: Check for wear, harm, or clogging. Inspect for leaks and make sure all additives are functional.

Cleaning: Clean the indicator, particularly glass tubes, to get rid of deposits and make sure clean visibility.

Testing: Regularly take a look at to affirm accuracy. For digital signs, preserve calibration as much as date.

Common Issues:

Inaccurate Readings: May end result from calibration troubles or blockages. Recalibrate or restore as needed.

Blockages: Sediment buildup in glass tubes can hinder readings. Regular cleansing prevents this.

Electrical Failures: For digital types, test for wiring troubles or sensor malfunctions.

Feed Water Pumps in Boiler Accessories

Feed water pumps are important in boiler systems, making sure a non-stop deliver of water to the boiler for steam generation. They play a key function in keeping gadget performance and stopping operational issues.

Function and Types

Feed water pumps supply water from a garage tank or supply to the boiler, keeping the important strain and go with the drift charge. There are numerous sorts of feed water pumps:

Centrifugal Pumps:

Function: Uses a rotating impeller to boom water velocity, that’s then transformed into strain.

Application: Ideal for slight strain programs because of their performance and simplicity.

Reciprocating Pumps:

Function: Employs a piston or plunger to push water thru a cylinder, producing excessive strain thru a back-and-forth motion.

Application: Suitable for excessive-strain programs wherein particular manage is wanted.

Gear Pumps:

Function: Utilizes interlocking gears to transport water, growing strain thru trapped water among gears.

Application: Provides a constant go with the drift and excessive strain, beneficial in numerous business programs.

Screw Pumps:

Function: Features a rotating screw that movements water thru the pump, producing strain thru helical movement.

Application: Effective for dealing with excessive-viscosity fluids and imparting consistent go with the drift.

How Feed Water Pumps Work

Feed water pumps perform with the aid of using drawing water from a supply and growing its strain earlier than handing over it to the boiler. The technique involves:

Intake: Water enters the pump thru an inlet.

Pressurization: The pump increases the water`s strain the use of mechanical mechanisms, together with impeller rotation or piston movement.

Delivery: The pressurized water is then despatched to the boiler, making sure it meets the desired go with the drift and strain.

Selection and Sizing

Choosing the proper feed water pump is important:

Flow Rate: Calculate the desired go with the drift charge primarily based totally at the boiler`s steam output and running conditions.

Pressure Requirements: Select a pump which can cope with the strain wanted to triumph over gadget resistance.

Type and Material: Choose a pump kind primarily based totally at the strain and go with the drift necessities and make certain cloth compatibility with the feed water.

Maintenance Tips

Proper upkeep extends the lifestyles of feed water pumps:

Regular Inspection: Check for wear, leaks, and uncommon noises.

Lubrication: Keep shifting components lubricated in step with producer guidelines.

Cleaning: Prevent blockages with the aid of using retaining the pump and additives clean.

Calibration: Ensure the pump operates at the suitable go with the drift charge and strain.

Part Replacement: Replace worn or broken components promptly.

Blow-off Valves in Boiler Accessories

Purpose and Function

The foremost cause of blow-off valves is to clean accrued particles and impurities from the boiler. This enables:

Maintain Efficiency: Removing sediments prevents blockages and scaling, that may lessen warmness switch performance and boom gasoline consumption.

Prevent Damage: Regular blow-off enables keep away from ability harm because of scale and sediment buildup, that may result in overheating and different operational problems.

Ensure Safety: Properly functioning blow-off valves make a contribution to universal gadget protection through stopping malfunctions associated with particles accumulation.

Types of Blow-off Valves

Several varieties of blow-off valves are utilized in boiler structures, every proper for exclusive applications:

Manual Blow-off Valves:

Description: Operated through hand the usage of a handwheel or lever. The operator manually opens and closes the valve to purge sediments.

Application: Ideal for smaller structures wherein guide operation is possible and effective.

Automatic Blow-off Valves:

Description: Equipped with an automatic mechanism that plays blow-off at scheduled durations or below unique conditions.

Application: Suitable for large structures or the ones requiring steady and automatic sediment elimination.

Continuous Blow-off Valves:

Description: Allows a non-stop glide of water to hold impurities in suspension and save you buildup.

Application: Used in structures desiring regular elimination of impurities to preserve water quality.

Combination Blow-off Valves:

Description: Integrates a couple of functions, which includes blow-off and drainage, right into a unmarried unit.

Application: Offers versatility and comfort in handling each blow-off and drainage tasks.

Operation and Maintenance

Effective operation and protection are important for blow-off valves:

Operation:

Manual Valves: Operate through turning the handwheel or lever to open or near the valve. Regularly carry out blow-off to get rid of accrued particles.

Automatic Valves: Program the valve to perform primarily based totally on gadget needs, making sure it plays blow-off at suitable durations.

Maintenance:

Inspection: Regularly test for wear, corrosion, and leaks.

Cleaning: Periodically smooth the valve and related piping to save you blockages.

Lubrication: Ensure transferring components are lubricated to keep away from sticking or malfunction.

Testing: Test the valve periodically to verify right operation.

Troubleshooting Common Problems

Address not unusualplace problems to preserve valve performance:

Valve Not Opening: Check for blockages or mechanical failure and smooth or restore as needed.

Leaks: Tighten connections or update seals. Replace the valve if the frame is damaged.

Inconsistent Blow-off: Adjust settings or test for operational problems.

Excessive Noise: Inspect for cavitation and make certain right operation inside designed parameters.

Economizers in Boiler Accessories

Economizers

Economizers are essential for reinforcing the performance of boiler structures with the aid of using improving waste warmth. Here`s a top level view in their definition, types, set up, benefits, and preservation considerations.

Definition and Purpose

Economizer: A warmth alternate tool that captures waste warmth from flue gases and makes use of it to preheat the feedwater coming into the boiler.

Purpose: To enhance boiler performance, lessen gasoline intake, and decrease emissions with the aid of using using exhaust warmth.

Types of Economizers

Vertical Economizers:

Design: Vertical warmth exchanger.

Application: Ideal for compact installations in restrained spaces.

Horizontal Economizers:

Design: Horizontal warmth exchanger.

Application: Common in huge centers for ease of preservation and get admission to.

Modular Economizers:

Design: Composed of a couple of smaller units.

Application: Offers flexibility for various capacities and machine sizes.

Condensing Economizers:

Design: Captures extra warmth with the aid of using condensing water vapor in flue gases.

Application: Maximizes warmth recovery, appropriate for high-performance structures.

Installation and Benefits

Installation:

Placement: Positioned among the boiler and the stack withinside the flue fueloline path.

Integration: Connected to the feedwater machine, following manufacturer

suggestions and protection codes.

Safety: Ensure right set up for preservation get admission to and stress relief.

Benefits:

Energy Savings: Reduces gasoline intake and lowers power payments with the aid of using preheating feedwater.

Extended Boiler Life: Reduces thermal stress, extending the boiler`s operational life.

Environmental Impact: Cuts greenhouse fueloline emissions with the aid of using enhancing gasoline performance.

Maintenance and Efficiency Considerations

Maintenance:

Inspection: Regular tests for wear, corrosion, and scale buildup.

Cleaning: Remove soot and particles to keep warmth switch performance.

Testing: Periodically take a look at to make sure right operation and performance.

Efficiency Considerations:

Heat Recovery: Assess and optimize the effectiveness of warmth recovery.

System Integration: Ensure right integration with the boiler and machine components.

Operational Monitoring: Monitor overall performance to cope with any performance deviations.

Economizers are critical for enhancing boiler machine performance, supplying widespread power and value financial savings even as lowering environmental impact. Proper set up, preservation, and tracking are key to maximizing their benefits.

Air Preheaters in Boiler Accessories

Air preheaters are crucial additives in boiler structures, designed to beautify performance via way of means of recuperating warmness from the flue gases and moving it to the incoming combustion air. This technique reduces gasoline intake and improves common gadget overall performance.

Role in Boiler Efficiency

Heat Recovery: Air preheaters seize waste warmness from flue gases to preheat the combustion air. This reduces the want for extra gasoline to attain the favored temperature and pressure.

Fuel Savings: By preheating the combustion air, much less gasoline is needed to gain the identical strength output, main to fee savings.

Improved Efficiency: Enhances boiler performance via way of means of recuperating and utilising warmness that might in any other case be wasted, ensuing in higher overall performance and decreased emissions.

Types of Air Preheaters

Rotary Air Preheaters:

Design: Consists of a rotating wheel with warmness switch surfaces that seize warmness from the flue gases and switch it to the combustion air.

Application: Commonly utilized in big business boilers for green warmness healing and non-stop operation.

Plate Type Air Preheaters:

Design: Features a chain of stacked plates with alternating warm flue gases and funky combustion air channels.

Application: Suitable for structures wherein area is confined and excessive warmness switch performance is needed.

Tubular Air Preheaters:

Design: Uses a chain of tubes via which combustion air and flue gases glide separately, permitting warmness switch via the tube walls.

Application: Often utilized in smaller structures or wherein unique warmness switch desires are present.

Regenerative Air Preheaters:

Design: Incorporates a thermal garage medium that absorbs warmness from flue gases and releases it to the combustion air in a cyclic technique.

Application: Effective in structures with variable hundreds and fluctuating temperatures.

Installation and Operation

Installation:

Placement: Installed among the boiler and the stack withinside the flue fueloline path, making sure ultimate warmness healing.

Integration: Properly combine with the combustion air gadget and make sure accurate alignment and connections.

Safety: Follow producer tips and protection codes to make sure accurate and secure installation.

Operation:

Heat Transfer: As flue gases byskip via the air preheater, warmness is transferred to the incoming combustion air, lowering gasoline desires.

Control: Monitor and alter operational settings to preserve ultimate overall performance and performance.

Maintenance Best Practices

Inspection:

Regular Checks: Inspect for symptoms and symptoms of wear, corrosion, and blockages. Ensure all additives are in correct circumstance and functioning properly.

Cleaning: Periodically easy the warmth trade surfaces to put off soot, scale, and particles that may obstruct warmness switch.

Maintenance:

Lubrication: Regularly lubricate transferring parts, consisting of the rotating wheel in rotary air preheaters, to make sure clean operation.

Repairs: Address any problems consisting of leaks, broken additives, or malfunctioning controls right away to keep away from overall performance losses.

Efficiency Monitoring:

Performance Checks: Monitor warmness healing performance and make sure the preheater is running inside its designed parameters.

Adjustments: Make vital changes primarily based totally on overall performance statistics to optimize performance and preserve powerful warmness switch.

Superheaters in Boiler Accessories

Superheaters are vital additives in steam boilers that growth the temperature of steam past its boiling point. By improving steam properties, they appreciably enhance boiler performance and overall performance.

Function and Importance

Function: A superheater increases the temperature of steam after it’s been generated withinside the boiler however earlier than it reaches the mills or different usage equipment. This technique includes heating steam to a better temperature to beautify its strength content material.

Importance:

Efficiency: By growing the steam temperature, superheaters enhance the performance of the boiler gadget. Higher temperature steam interprets into extra powerful strength switch to mills, ensuing in higher gasoline usage and decrease working costs.

Performance: Superheated steam incorporates extra strength, which reinforces the general overall performance of the steam-pushed machinery, growing energy output and operational performance.

Reduced Corrosion: Superheated steam has decrease moisture content material in comparison to saturated steam, which facilitates reduce corrosion and scaling in mills and different downstream equipment.

Types of Superheaters

Radiant Superheaters:

Design: Positioned at once withinside the furnace in which they take in warmth from the combustion technique.

Application: Suitable for high-temperature applications, in which direct warmth absorption is critical.

Convection Superheaters:

Design: Located withinside the flue fueloline route to take in warmth from the recent gases passing over them.

Application: Often used along radiant superheaters to optimize warmth absorption and manipulate steam temperature.

Combined Superheaters:

Design: Integrate each radiant and convection heating methods.

Application: Provides flexibility and performance via way of means of utilising a couple of warmth reassets for steam superheating.

Attemperators:

Design: Adjust steam temperature via way of means of injecting water into the steam go with the drift to modify temperature precisely.

Application: Essential for structures requiring specific manipulate of steam temperature and strain.

Installation Procedures

Placement: Install superheaters withinside the flue fueloline route or furnace in step with layout specifications, making sure superior warmth absorption.

Integration: Connect superheaters to the steam and water structures with right alignment and steady connections.

Safety: Adhere to producer tips and protection codes for the duration of set up to make sure secure operation and protection access.

Maintenance and Troubleshooting

Maintenance:

Inspection: Regularly take a look at for wear, corrosion, and scaling on superheaters. Look for leaks or harm to warmth alternate surfaces.

Cleaning: Periodically easy the superheater to take away soot, scale, and different deposits that might impair warmth switch.

Testing: Conduct overall performance assessments to confirm that the superheater operates inside its designed temperature and strain ranges.

Troubleshooting:

Temperature Fluctuations: Investigate warmth supply troubles or manipulate gadget malfunctions. Ensure attemperators, if used, are functioning correctly.

Scaling and Deposits: Address via way of means of cleansing and, if needed, the use of chemical remedies to save you buildup.

Leaks and Corrosion: Repair leaks right away and update corroded additives to hold performance.

Performance Issues: Monitor gadget overall performance and regulate operational parameters to make sure superior operation.

Frequently Asked Questions (FAQs)

- What is the purpose of a superheater in a boiler system?

A superheater’s main purpose is to increase the temperature of steam beyond its boiling point. By doing so, it enhances the energy content of the steam, leading to improved boiler efficiency, better performance, and reduced corrosion in downstream equipment.

2. How does a superheater improve boiler efficiency?

A superheater improves boiler efficiency by preheating steam to higher temperatures. This means that the energy content of the steam is greater, which enhances the effectiveness of energy transfer to turbines or other machinery, resulting in better fuel utilization and lower operational costs.

3. How is a superheater installed in a boiler system?

Superheaters are typically installed in the flue gas path or furnace of a boiler system. They must be positioned to maximize heat absorption from the combustion gases or furnace. Proper integration with the steam and water systems is essential, and installation should follow manufacturer guidelines and safety codes.

4. How do attemperators work in conjunction with superheaters?

Attemperators control the temperature of superheated steam by injecting water into the steam flow. This adjustment ensures that the steam temperature is maintained within desired limits, allowing for precise control of the steam’s thermal properties.

5. Why is it important to maintain a superheater?

Regular maintenance is crucial to ensure that the superheater continues to operate efficiently. Proper upkeep prevents performance issues, extends the lifespan of the equipment, and avoids potential safety hazards or costly repairs.