A single plate clutch is a essential element withinside the transmission structures of many vehicles, regarded for its simplicity and efficiency. It serves the essential motive of attractive and disengaging the pressure from the engine to the transmission, thereby controlling the electricity waft to the wheels. This type of clutch is characterized with the aid of using its unmarried friction plate, which gives a right away and dependable connection among the engine and the gearbox. Single plate clutches are predominantly used in passenger cars, motorcycles, and mild vans because of their truthful layout and cost-effectiveness.

- Components of Single Plate Clutch

- Working Principle of Single Plate Clutch

- Types of Single Plate Clutches

- Materials Used in Single Plate Clutches

- Advantages of Single Plate Clutch

- Disadvantages of Single Plate Clutch

- Maintenance of Single Plate Clutch

- Common Issues and Troubleshooting

- Frequently Asked Question (FAQs)

Components of Single Plate Clutch

Main Parts and Their Functions

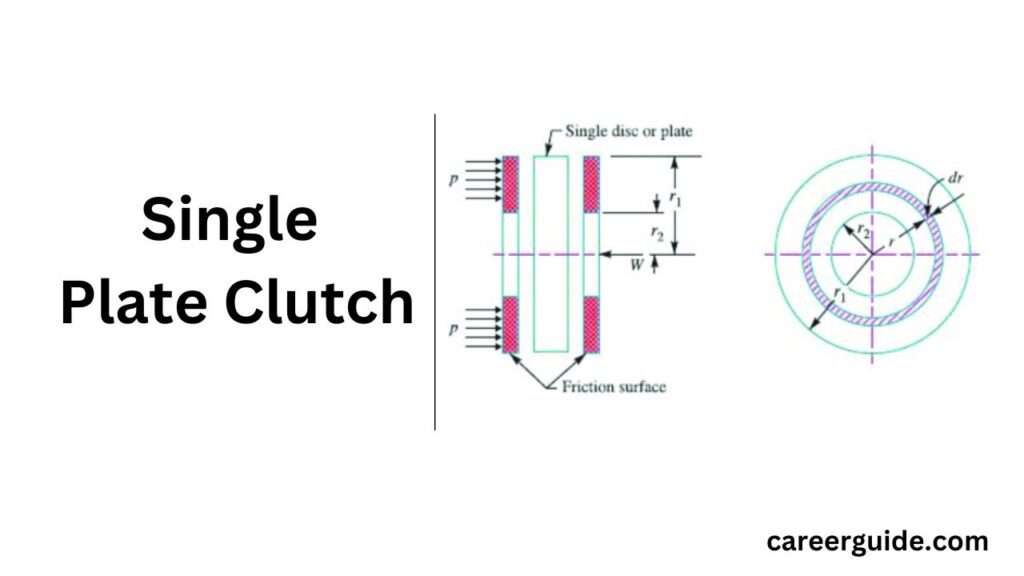

A single plate clutch includes numerous key components, every gambling a essential position in its operation. Understanding those components and their features is vital for greedy how the grasp machine works as a whole.

Clutch Plate: Also known as the friction disc, that is the primary issue that transmits torque from the engine to the transmission. It is covered with friction cloth on each facets to make sure a stable grip and clean energy switch whilst engaged.

Pressure Plate: This component applies stress to the grasp plate to have interaction it with the flywheel. When the grasp pedal is released, the stress plate is pressured in opposition to the clutch plate, growing friction and transmitting engine energy to the transmission.

Flywheel: Attached to the engine`s crankshaft, the flywheel presents a clean floor for the grasp plate to have interaction with. It additionally enables in smoothing out the energy pulses from the engine, contributing to smoother automobile operation.

Clutch Cover: Also called the grasp housing or cowl assembly, this issue encases the grasp assembly, defensive it from dirt and debris. It additionally homes the diaphragm spring or coil springs that follow stress to the stress plate.

Release Bearing: Also called the throw-out bearing, this issue enables in disengaging the grasp. When the grasp pedal is pressed, the discharge bearing pushes in opposition to the stress plate’s launch fingers, inflicting the stress plate to transport farfar from the grasp plate, thereby disengaging the grasp.

Diaphragm Spring: Found in most modern clutches, this spring applies the essential pressure to the stress plate to have interaction the grasp. When the grasp pedal is pressed, the diaphragm spring flexes, permitting the stress plate to transport farfar from the grasp plate.

Working Principle of Single Plate Clutch

How It Operates

The single plate clutch operates on a honest principle, counting on friction to interact and disengage the engine from the transmission. Here is a step by step rationalization of ways it works:

Engagement (Power Transmission)

Clutch Pedal Released: When the driving force releases the grasp pedal, the diaphragm spring or coil springs withinside the grasp cowl follow strain to the strain plate.

Pressure Plate Engagement: The strain plate, beneathneath the pressure of the springs, presses in opposition to the grasp plate, that is sandwiched among the strain plate and the flywheel.

Friction Grip: The friction material at the grasp plate grips the flywheel`s surface, permitting engine torque to be transmitted thru the clutch plate to the transmission enter shaft.

Power Flow: The engine`s rotational electricity is transferred to the transmission, permitting the automobile to transport.

Disengagement (Interrupting Power Transmission)

Clutch Pedal Pressed: When the driving force presses the grasp pedal, the pressure is transmitted thru the grasp linkage or hydraulic gadget to the discharge bearing.

Release Bearing Action: The launch bearing movements closer to the strain plate, pushing in opposition to the diaphragm spring or the discharge hands of the strain plate.

Pressure Plate Movement: This motion reasons the strain plate to transport farfar from the grasp plate, decreasing the strain on it.

Separation: As the pressure is released, the grasp plate loses touch with the flywheel, interrupting the transmission of engine electricity to the transmission.

Free Spinning: The grasp plate and the transmission enter shaft can now spin independently of the engine, permitting the driving force to extrade gears with out transmitting electricity.

Re-Engagement

Gradual Contact: When the driving force begins offevolved to launch the grasp pedal again, the strain plate step by step applies strain returned onto the grasp plate.

Friction Re-Establishment: The grasp plate slowly re-establishes frictional touch with the flywheel, making sure a easy engagement.

Full Power Transmission: Once the grasp pedal is absolutely released, the grasp plate is firmly pressed in opposition to the flywheel, and complete electricity transmission resumes.

Types of Single Plate Clutches

Variations and Their Uses

Single plate clutches are available in distinct versions to in shape diverse packages and overall performance necessities. Here are the primary types:

Dry Clutch

Description: The maximum common form of single plate clutch, in which the seize plate and friction fabric aren’t immersed in lubricating oil.

Uses: Found in maximum passenger cars, mild trucks, and a few bikes because of its simplicity and cost-effectiveness.

Wet Clutch

Description: In this type, the clutch plate is immersed in lubricating oil, commonly inside a housing that maintains the additives constantly lubricated.

Uses: Commonly utilized in bikes, ATVs, and a few heavy-obligation packages in which smoother engagement and warmth dissipation are critical. Wet clutches can cope with better torque hundreds and offer longer operational lifestyles in comparison to dry clutches.

Considerations for Choosing Between Dry and Wet Clutches

Friction Characteristics: Dry clutches generally tend to have extra abrupt engagement and disengagement in comparison to moist clutches, which give smoother operation.

Heat Dissipation: Wet clutches expend warmth extra successfully because of the presence of lubricating oil, making them appropriate for high-overall performance and heavy-obligation packages.

Maintenance: Wet clutches require periodic oil adjustments and protection of the lubrication device, whilst dry clutches are normally protection-loose on this regard.

Understanding the variations among those forms of unmarried plate clutches facilitates in choosing the appropriate clutch device primarily based totally at the vehicle`s necessities for overall performance, durability, and operational characteristics.

Materials Used in Single Plate Clutches

Friction Material

Asbestos-Based Materials

Description: Traditionally used for its excellent warmth resistance and friction houses.

Properties: High temperature tolerance, properly frictional overall performance, and sturdiness.

Usage: Due to fitness risks related to asbestos, its use has extensively declined and has been changed with the aid of using non-asbestos alternatives.

Organic Compounds

Description: Made from a mixture of resin, rubber, and different natural fibers.

Properties: Good friction characteristics, much less abrasive to the flywheel and strain plate, and environmentally friendly.

Usage: Commonly utilized in maximum present day motors as a more secure opportunity to asbestos.

Ceramic Materials

Description: Composed of ceramic fibers blended with copper or steel.

Properties: Extremely excessive warmth resistance, exquisite put on resistance, and excessive friction coefficient.

Usage: Often determined in excessive-overall performance and racing packages because of their cappotential to deal with excessive conditions.

Metal Components

Steel

Description: Used withinside the creation of the take hold of plate, strain plate, and flywheel.

Properties: High energy, sturdiness, and properly warmth dissipation.

Usage: Standard fabric for maximum unmarried plate take hold of additives because of its stability of overall performance and cost.

Cast Iron

Description: Sometimes used for the flywheel and strain plate because of its exquisite casting houses and vibration damping.

Properties: High put on resistance, properly machinability, and damping characteristics.

Usage: Preferred in packages wherein vibration discount is important.

Composite Materials

Carbon-Carbon Composites

Description: Advanced composite fabric utilized in excessive-overall performance clutches.

Properties: Extremely excessive energy-to-weight ratio, exquisite warmth resistance, and minimum thermal expansion.

Usage: Found in racing automobiles and excessive-overall performance sports activities automobiles wherein weight loss and overall performance are critical.

Other Materials

Kevlar

Description: High-energy artificial fiber utilized in friction linings.

Properties: High put on resistance, properly warmth resistance, and lengthy lifespan.

Usage: Used in overall performance and heavy-responsibility clutches wherein sturdiness is essential.

Advantages of Single Plate Clutch

Simplicity and Reliability

Ease of Design and Manufacturing: The single plate clutch has a truthful layout, making it less difficult to fabricate and keep.

Less Complex Mechanism: Fewer elements imply fewer factors of failure, improving reliability and lowering preservation needs.

Efficient Power Transmission

Direct Connection: The single plate clutch presents an instantaneous mechanical hyperlink among the engine and the transmission, making sure green electricity transfer.

Minimal Power Loss: The layout minimizes electricity loss in the course of transmission, contributing to higher gasoline performance and automobile overall performance.

Smooth Engagement and Disengagement

Controlled Operation: The clutch permits for easy engagement and disengagement of electricity, imparting a snug riding experience.

Reduced Wear and Tear: Smooth operation reduces put on on transmission components, extending the lifespan of the automobile`s drivetrain.

Cost-Effective

Lower Production Costs: The easy layout of the unmarried plate snatch interprets to decrease production fees in comparison to extra complicated snatch systems.

Affordable Maintenance: Replacement elements and preservation offerings for unmarried plate clutches are commonly extra affordable, lowering the general price of automobile ownership.

Wide Range of Applications

Versatility: Single plate clutches are appropriate for a huge variety of vehicles, from passenger automobiles to mild vehicles and motorcycles.

Adaptability: They may be tailored to distinctive automobile designs and overall performance requirements, making them a flexible preference for manufacturers.

Effective Heat Dissipation

Material Efficiency: Materials utilized in unmarried plate clutches, which includes metal and natural friction materials, are powerful at dissipating warmness generated in the course of operation.

Thermal Management: Good warmness dissipation houses assist save you overheating and keep steady overall performance.

Compact Design

Space-Saving: The compact layout of single plate clutches permits them to match without difficulty inside the constrained areas of cutting-edge vehicles.

Weight Reduction: The light-weight nature of the unmarried plate snatch contributes to the general weight loss of the automobile, enhancing gasoline performance and handling.

Ease of Operation

Driver Comfort: The single plate clutch is designed for ease of use, imparting a easy and snug riding experience.

Reduced Driver Fatigue: The truthful operation of the snatch reduces driving force fatigue, particularly in stop-and-cross visitors conditions.

Disadvantages of Single Plate Clutch

Limited Torque Capacity

Torque Limitations: Single plate clutches might not deal with very excessive torque hundreds as successfully as multi-plate clutches. This can restrict their use in excessive-overall performance or heavy-obligation cars that require extra torque transmission.

Risk of Slipping: Under excessive torque conditions, a unmarried plate seize might also additionally enjoy slipping, that may lessen overall performance and motive untimely put on.

Heat Generation

Heat Buildup: Single plate clutches can generate considerable warmth for the duration of operation, specially below heavy hundreds or for the duration of competitive riding. Excessive warmth can have an effect on overall performance and cause seize fade.

Overheating Risks: If now no longer well managed, warmth buildup can motive harm to the friction substances and different seize additives, doubtlessly main to failure.

Wear and Tear

Friction Material Degradation: The friction cloth at the seize plate wears out through the years because of steady friction and warmth. This put on can have an effect on the seize`s overall performance and require normal alternative.

Maintenance Needs: Frequent put on and tear necessitate normal renovation and capability alternative of additives, which may be high priced and inconvenient.

Less Smooth Operation Compared to Modern Systems

Engagement Abruptness: Compared to superior seize structures like dual-seize transmissions or constantly variable transmissions (CVTs), unmarried plate clutches might also additionally offer much less easy engagement and disengagement.

Driver Experience: The extra primary engagement mechanism can bring about a much less subtle riding enjoy, particularly in stop-and-pass traffic.

Limited Adaptability for Some Applications

High-Performance Vehicles: For cars requiring extraordinarily excessive overall performance and durability, along with racing cars, unmarried plate clutches might not offer the vital overall performance characteristics.

Specialized Vehicles: In packages like heavy-obligation vehicles or off-avenue cars, unmarried plate clutches might not provide the robustness or adaptability wanted for most beneficial overall performance.

Potential for Noise and Vibration

Operational Noise: Single plate clutches can produce noise for the duration of engagement and disengagement, particularly if the additives are worn or misaligned.

Vibration Issues: In a few cases, vibrations may be transmitted via the seize system, doubtlessly affecting automobile consolation and overall performance.

Difficulty in Handling Extreme Conditions

Extreme Temperatures: Single plate clutches might also additionally battle in extraordinarily excessive or low-temperature conditions, that may have an effect on their overall performance and longevity.

Heavy Loads: Clutches that aren’t designed for heavy hundreds might also additionally battle to perform successfully below strenuous conditions.

Lower Torque Capacity Compared to Multi-Plate Clutches

Multi-Plate Alternatives: Multi-plate clutches provide better torque capacities and are extra appropriate for excessive-overall performance or heavy-obligation packages. Single plate clutches might not fit the overall performance of those options in such scenarios.

Maintenance of Single Plate Clutch

Regular Inspection

Check for Wear: Periodically inspect the snatch plate and different additives for symptoms and symptoms of put on, along with thinning friction fabric or choppy surfaces.

Monitor Performance: Pay interest to any adjustments in snatch overall performance, along with slipping, issue in engagement, or uncommon noises.

Proper Clutch Adjustment

Pedal Free Play: Ensure that the clutch pedal has the ideal quantity of loose play. Too tons or too little loose play can have an effect on snatch engagement and disengagement.

Cable or Hydraulic Adjustment: If your car makes use of a cable or hydraulic device for snatch actuation, make sure it’s miles nicely adjusted in keeping with the manufacturer`s specifications.

Avoid Overloading

Gradual Engagement: Avoid surprising or competitive snatch engagement, particularly whilst beginning from a standstill. Gradual engagement allows lessen put on at the friction materials.

Avoid Excessive Towing: Refrain from overloading the car or towing heavy hundreds that exceed the snatch`s torque capacity, as this could result in untimely put on.

Heat Management

Proper Ventilation: Ensure that the snatch meeting is satisfactorily ventilated to deplete warmness effectively. Avoid riding in situations that reason immoderate warmness buildup.

Monitor Temperature: In automobiles with superior temperature tracking systems, preserve a watch on snatch temperature to save you overheating.

Smooth Driving Habits

Avoid Riding the Clutch: Do now no longer preserve your foot at the snatch pedal at the same time as riding, as this reasons pointless put on at the snatch additives.

Shift Gears Smoothly: Practice easy equipment moving to decrease strain at the snatch and transmission additives.

Regular Fluid Checks

Hydraulic Fluid Levels: For automobiles with a hydraulic snatch device, frequently test and pinnacle up the snatch fluid as needed. Low fluid stages can have an effect on snatch operation.

Inspect for Leaks: Check for any leaks withinside the hydraulic device or across the snatch meeting, as those can result in overall performance issues.

Proper Installation

Follow Manufacturer`s Guidelines: When changing or putting in a brand new snatch, comply with the manufacturer`s tips to make sure accurate set up and alignment.

Use Quality Parts: Use great substitute elements to keep the integrity of the snatch device and keep away from untimely failure.

Addressing Problems Early

Prompt Repairs: Address any symptoms and symptoms of snatch problems, along with slipping, noise, or issue in attractive gears, as quickly as they arise. Early intervention can save you similarly harm and highly-priced repairs.

Seek Professional Help: If you’re uncertain approximately diagnosing or repairing snatch issues, seek advice from a expert mechanic with understanding in snatch systems.

Common Issues and Troubleshooting

Common Issues

Clutch Slipping

Symptoms: Engine revs up with out corresponding acceleration, issue in retaining speed, or a burning smell.

Possible Causes: Worn friction material, misadjusted grasp, or oil contamination.

Difficulty in Shifting Gears

Symptoms: Hard or noisy equipment shifts, grinding noises whilst converting gears, or gears slipping out of engagement.

Possible Causes: Clutch now no longer absolutely disengaging, worn synchronizers, or linkage troubles.

Clutch Pedal Issues

Symptoms: Pedal feels too gentle or too hard, pedal engagement is inconsistent, or the pedal is sticking.

Possible Causes: Air withinside the hydraulic device, a defective grasp grasp or slave cylinder, or misadjusted grasp cable.

Clutch Noise

Symptoms: Unusual noises inclusive of squealing, rattling, or grinding whilst the grasp is engaged or disengaged.

Possible Causes: Worn bearings, broken stress plate, or misaligned grasp components.

Clutch Vibration

Symptoms: Vibrations or shaking whilst the grasp is engaged or whilst driving.

Possible Causes: Imbalanced grasp plate, worn flywheel, or broken stress plate.

Troubleshooting and Fixing Problems

Addressing Clutch Slipping

Inspect Friction Material: Check the situation of the grasp plate and update it if worn.

Check for Oil Contamination: Ensure there may be no oil or fluid leakage at the grasp components. Clean or update any infected parts.

Adjust Clutch: Ensure right adjustment of the grasp pedal or hydraulic device to enhance engagement.

Examine the Flywheel: Check for symptoms and symptoms of damage or harm at the flywheel and resurface or update it as needed.

Test Drive: After making changes or replacements, check pressure the car to verify that the slipping difficulty is resolved.

Resolving Gear Shifting Issues

Adjust Clutch Linkage: Ensure that the grasp linkage or hydraulic device is well adjusted for complete disengagement.

Inspect Synchronizers: Check for worn synchronizers and update them if necessary.

Bleed the Clutch System: For hydraulic systems, bleed the device to put off any air that might have an effect on shifting.

Check for Cable Wear: Inspect the grasp cable for put on or harm and update it if needed.

Consult a Mechanic: If troubles persist, are seeking expert assist to diagnose and cope with greater complicated problems.

Fixing Clutch Pedal Problems

Check Hydraulic Fluid: For hydraulic systems, make sure the grasp fluid stage is accurate and pinnacle up if necessary.

Inspect for Leaks: Check for leaks withinside the hydraulic device or across the grasp assembly.

Adjust Pedal Free Play: Adjust the grasp pedal unfastened play to make sure right engagement and disengagement.

Examine Master and Slave Cylinders: Inspect the grasp grasp and slave cylinders for faults and update them if defective.

Test Operation: After changes or repairs, check the grasp pedal to make sure right function.

Freqently Asked Questions (FAQs)

1. What is a single plate clutch?

A single plate clutch is a type of clutch system where a single friction plate is used to engage and disengage the engine from the transmission, providing a simple and efficient means of power transfer.

2. What are the main components of a single plate clutch?

The main components include the clutch plate, pressure plate, flywheel, release bearing, and clutch pedal (or hydraulic system).

3. How does a single plate clutch work?

It operates by pressing the clutch pedal to disengage the engine from the transmission, allowing for smooth gear changes. When the pedal is released, the friction plate engages with the flywheel to transfer power.

4. What are the common types of single plate clutches?

The common types include dry clutches and wet clutches. Dry clutches are not immersed in oil, while wet clutches are lubricated with oil to improve performance and longevity.

5. What materials are used in single plate clutches?

Common materials include organic compounds, ceramic materials, steel, cast iron, and composite materials like carbon-carbon and Kevlar.